Additional capacity will accommodate RFID orders for non-apparel products, including electronics, automotive, toys, healthcare, food, and home goods

NORCROSS, GA – March 7, 2024 — FineLine Technologies has strengthened its position as the largest service bureau in the U.S. for barcode and RFID products and solutions with a $2.5 million equipment acquisition and an expansion of its Data2 division’s O’Fallon, MO, production facility. The investment includes an array of RFID converting equipment and an enlargement of the existing plant’s manufacturing footprint to 50,000 sq. ft. With facilities in Atlanta, St. Louis and Costa Mesa, CA, Fineline’s U.S.-wide manufacturing space now exceeds130,000 sq. ft.

According to Fineline Chairman & CEO George Hoffman, the investment supports the increasing demand for RFID item labeling on non-apparel products and brands’ needs to comply with recent mandates from several major retailers.

“RFID has been embraced for decades by apparel retailers as a way to correct historically poor inventory accuracy and improve on-shelf availability,” Hoffman says. “During the pandemic, retailers across the board responded to crowd-avoidance by adopting omnichannel strategies which are heavily dependent upon having accurate inventories, which are obtainable only with RFID item tagging. Consequently, the use cases for RFID item tagging are increasing, and the breadth of products covered is rapidly expanding to include non-apparel items such as home goods, automotive and industrial components, toys, electronics, and crafts.”

Hoffman adds that successful RFID compliance by brands involves reliable RFID label supply that can be customized to the unique needs of each brand, along with knowledge of how to meet retailer specifications for inlay type, encoding schema, form factors and application processes.

“By expanding our RFID manufacturing capacity and capabilities, we can assist customers in meeting these challenges on an even larger scale,” he says. “Besides our knowledge of retailers’ unique RFID labeling requirements and each step of the Auburn qualification process, we provide a broad selection of RFID sensors, adhesives technology, high-quality graphics printing with RFID integration and 100%-inspected rolls required for automatic label application.”

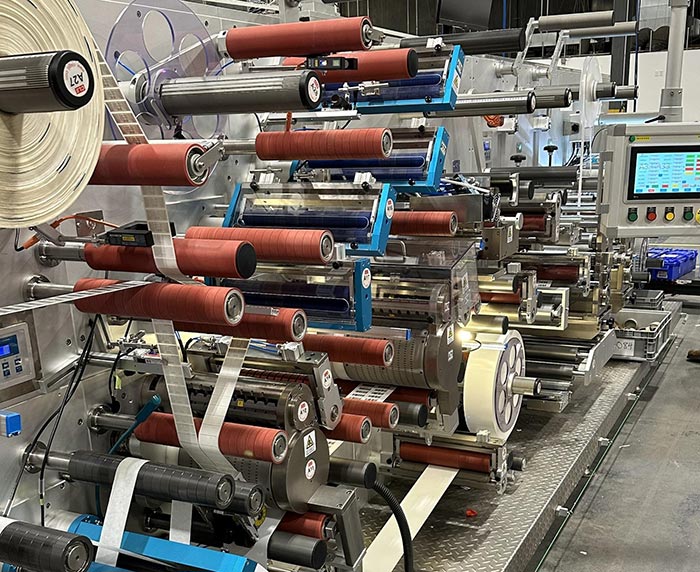

New equipment at Fineline’s Data2 division O’Fallon plant

New equipment installed at Fineline’s Data2 division O’Fallon, Mo., plant includes rotary digital printers, high-capacity RFID label inserters, RFID printer/encoders, a 10-station rotary die cutter and roll-to-roll RFID verification equipment.

Capabilities include:

- High-speed digital and flexographic, four-color process, rotary printing

- RFID inlay integration of dry inlays, for customized label designs

- High-speed RFID encoding and verification

- Prime Labels and Engineered, multi-layered label constructions

- High-capacity and quick-turn RFID label finishing

In addition, the FineLine O’Fallon facility includes on-premise RFID and materials testing labs to ensure customers’ RFID labels meet the latest retailer performance requirements.

Wide web RFID label inserter is part of Fineline’s $2.5MM equipment investment, which strengthens the company’s position as the largest RFID and bar code service bureau in the U.S.

About FineLine

FineLine Technologies provides barcode and RFID-integrated labels, tags, and secure credentials to enhance supply chains, omnichannel fulfillment, POS, access control, and consumer engagement. FineLine produces and delivers billions of tickets and labels annually through its network of global print hubs to companies in industries around the world in less than five days on average.

With a network of more than 80,000 registered suppliers, customers benefit from fast and easy online order placement, immediate tracking, and valuable analytics for even the most complex business logistics. Learn more at finelinetech.com.

Contact:

Marketing Communications

marketing@finelinetech.com

+1 800 500 8687